To find out more about any of our products or services call (+44 or 0)116 276 4242 now!

Ovens for Reflow

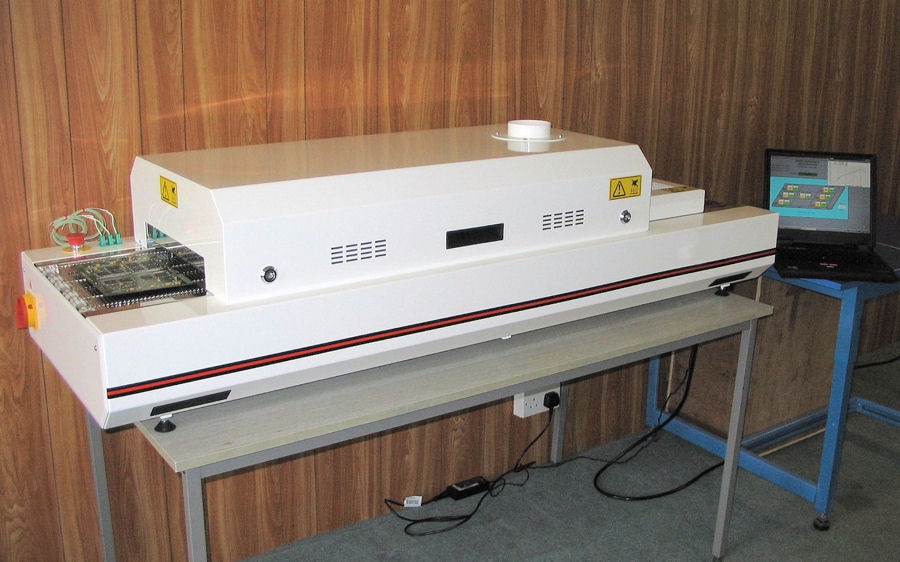

We have designed a range of conveyor ovens for many applications. These top quality ovens represent the best in low cost, high performance solder reflow systems. Three sizes are now available - 250mm, 300mm, and 450mm belt width.

Our new design utilises the very best of convection plus radiant heat processing techniques. Reliable and consistent in operation, efficient in power consumption, easy to control, trouble free, and such good value for money.

- Safe processing of all SMD components. Double sided assemblies, BGA assemblies, fine pitch ICs, hidden chip components - No problem!

- More efficient and controllable than pure convection systems.

- Closed loop microprocessor temperature control in each zone.

- Product heating is exceptionally consistent due to the reliability of quick response ceramic long wave elements with the benefits of forced convection for all-round edge to edge heating.

- "Single profile" processing for the majority of substrates.

- Minimal thermal stress, no shadowing or colour sensitivity.

- Full production or small batches may be run with no profile change or instability.

- "Nose to tail" product loading is easily accommodated.

- Stainless steel mesh conveyor belt.

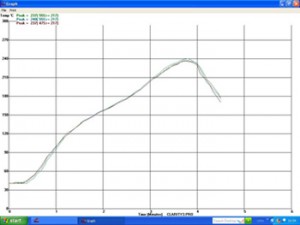

- Built-in profile temperature display.

- High performance, but low in capital and running costs.

Euroflow Details

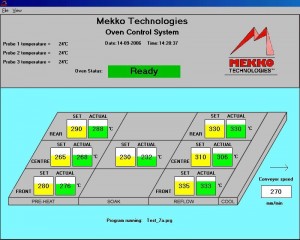

Our new Euroflow design includes a new heater control system designed to overcome the most common problem with lead-free soldering, which is the varying temperature across the substrate. The ovens are divided into pre-heat, soak and reflow zones along the length of the conveyor, but we also have zones of control across the conveyor. So the heat input is controlled from edge to edge over the whole width of the conveyor, ie front edge, centre, and back edge. This means that the operator can now easily overcome the problem of temperature variation across the substrate.

- Two sided boards, fine pitch ICs, BGA assemblies, hidden chip components - No problem!

- No shaddowing or colour sensitivity.

- New "Euroflow" design for thermal uniformity.

- High performance with low energy consumption compared with hot air systems!

By using a combination of quick response, long-wave ceramic heater panels within the processing chamber with hot air convection flow, power consumption is kept to a minimum. And yet thermal stability is so optimised to allow for "nose to tail" p.c.b. loading, and single-profile processing is used for the majority of substrate types. Full production or small batches may be run with no profile change and no instability.

EuroFlow 250C

250mm wide conveyor

Heated length = 600mm + 300mm cooling zone

Euroflow cross-belt temperature control with PC computer control system

Maximum heater power 3.8kW

Average power 2.0kW

EuroFlow 300C

300mm wide conveyor

Heated length = 900mm + 300mm cooling zone

Euroflow cross-belt temperature control with PC computer control system

Maximum heater power 5.7kW

Average power 3.0kW

EuroFlow 350C

350mm wide conveyor

Heated length - 1,200mm + 600mm cooling zone

Euroflow cross-belt temperature control with PC computer control system

Maximum heater power 8kW

Average power 5kW

EuroFlow 450C

450mm wide conveyor

Heated length = 1,200mm + 600mm cooling zone

Euroflow cross-belt temperature control with PC computer control system

Maximum heater power 11kW

Average power 6kW

CR220

250mm wide conveyor

Heated length = 600mm + 300mm cooling zone

2 x Omron temperature controllers

Maximum heater power 2.4kW

Average power 1.5kW

CR300

300mm wide conveyor

Heated length = 900mm + 300mm cooling zone

4 x Omron temperature controllers

Maximum heater power 4.2kW

Average power 2.5kW

CR300PC

300mm wide conveyor

Heated length = 900mm + 300mm cooling zone

PC computer control system

Maximum heater power 4.2kW

Average power 2.5kW

For more information or to place an order

Telephone: (+44 or 0)116 276 4242

Or complete the form below and we will call you back as soon as possible.

European Partners

Website - www.factronix.com

Email -

Website - www.hoang-pvm-engineering.com

Email -

Website - www.piediffusion.com

Email -

Website - www.ab-electronic.com

Email -

Website - www.elmisrl.it

Email -

Website - www.eltraco.com

Email -

Website - www.npo-diod.com/

Email -

Website - www.esd-line.ru

Email -

Website - www.paktel.pl

Email -